Design

Design

Optimize and Work Efficiently

By Using Advanced CAD/CAM/CAE Applications.

To improve quality and shorten delivery time during mold manufacturing, we continue to invest in high precision facilities such as high speed and precision CNC, automated high precision wire EDM, double density injection machine, high-pressure injection machine, optical QC equipment, and etc.

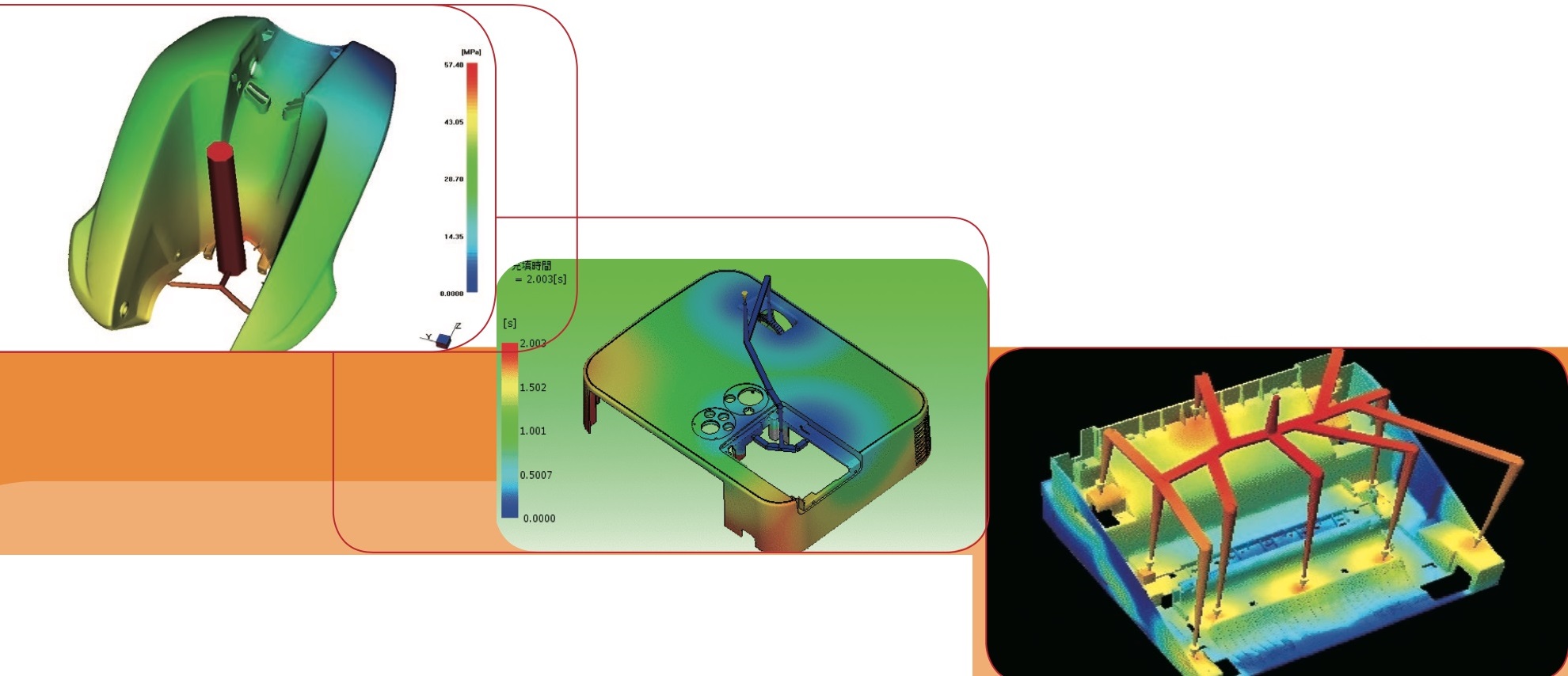

Nowadays, a precise mold requires a series of steps, which is development, designing, manufacturing, and trial test, to be able to satisfy Customers' expectation in terms of quality and delivery time. Both development and designing stages are critical factors to success. Our designing team keeps up with the advancement of info-technology in the world, using all kinds of software applications to acquire firsthand mold details and analysis reports.

We continue to invest in developing software (CAD/CAM/CAE). Similarly, with the aid from MOLD FLOW simulation application (CAE), we are able to determine or diagnose with mold before manufacture begin and come up with a better mold structure and processing method.

| DESCRIPTION | WORKING AREA |

| AUTO CAD | 2D MOLD DESIGN |

| AUTO CAD INVENTOR | 2D MOLD DESIGN |

| PRO/ENGINEER | 3D CAD/CAM |

| UNIGRAPHICS NX | 3D CAD |

| POWER MILL/SHAP | 3D CAD/CAM |

| SOLIDWORKS | 3D CAD |

| CIMATRON | 3D CAD/CAM |

| CATIA | 3D CAD |

| MOLD FLOW | MOLD FLOW/CAE |

- MOLD FLOW ANALYSIS